**Fiber Laser Market Trends, Growth, and Forecast 2025-2033**]

<p><strong>Market Overview:</strong></p>

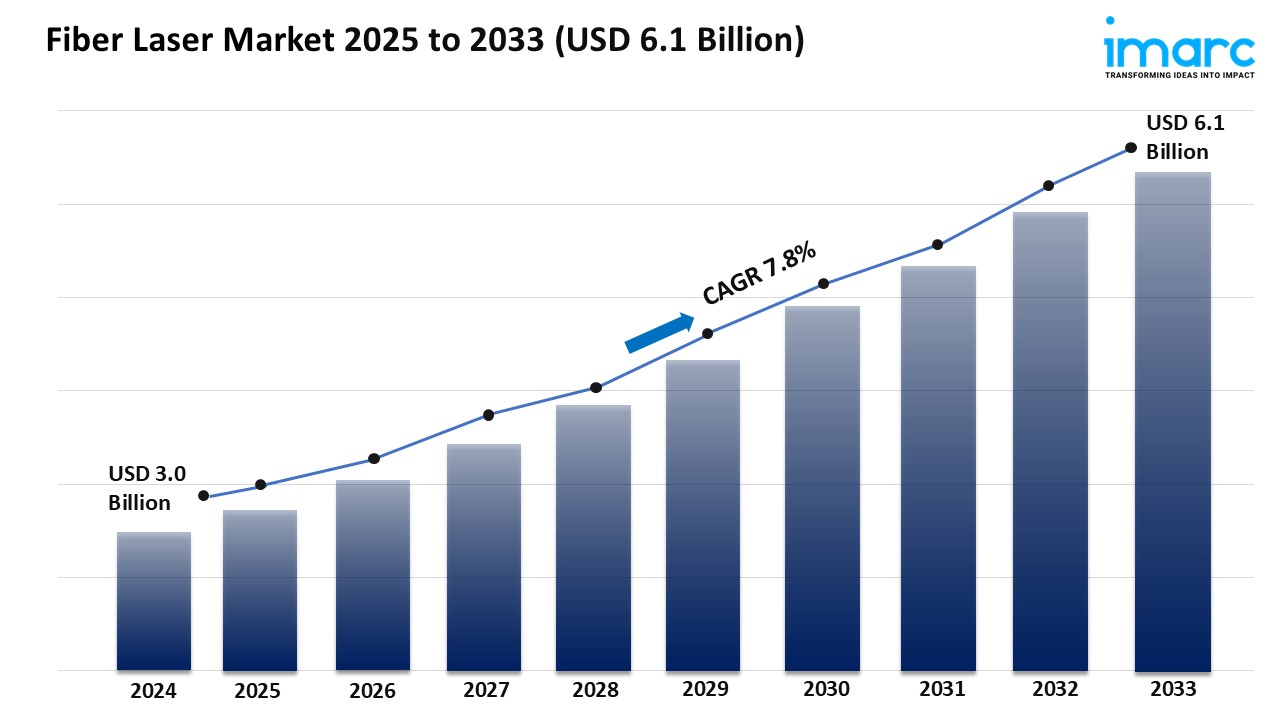

<p><span style="font-weight: 400;">The fiber laser market is experiencing rapid growth, driven by rapid adoption in the electric vehicle (EV) and Battery sector, integration with industry 4.0 and smart manufacturing, and miniaturization and precision in semiconductor & electronics. According to IMARC Group's latest research publication, </span><strong>"Fiber Laser Market Report by Type (Infrared Fiber Laser, Ultraviolet Fiber Laser, Ultrafast Fiber Laser, Visible Fiber Laser), Application (Cutting, Welding, Marking, Fine and Micro Processing, Medical, and Others), and Region 2025-2033", </strong><span style="font-weight: 400;">the global fiber laser market size reached </span><strong>USD 3.0 Billion</strong><span style="font-weight: 400;"> in 2024. Looking forward, IMARC Group expects the market to reach </span><strong>USD 6.1 Billion</strong><span style="font-weight: 400;"> by 2033, exhibiting a growth rate </span><strong>(CAGR) of 7.8%</strong><span style="font-weight: 400;"> during 2025-2033.</span></p>

<p><span style="font-weight: 400;">This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.</span></p>

<p><strong>Download a sample PDF of this report:</strong><a href="https://www.imarcgroup.com/fiber-laser-market/requestsample"> <strong>https://www.imarcgroup.com/fiber-laser-market/requestsample</strong></a></p>

<p><strong>Our report includes:</strong></p>

<ul>

<li style="font-weight: 400;"><span style="font-weight: 400;">Market Dynamics</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Market Trends and Market Outlook</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Competitive Analysis</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Industry Segmentation</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Strategic Recommendations</span></li>

</ul>

<p><strong>Growth Factors in the Fiber Laser Market</strong></p>

<ul>

<li style="font-weight: 400;"><strong>Rapid Adoption in the Electric Vehicle (EV) and Battery Sector</strong></li>

</ul>

<p><span style="font-weight: 400;">The mass transition of the automotive industry toward electrification is a core driver for the fiber laser market. Manufacturing Electric Vehicle (EV) battery packs, which are complex assemblies requiring precise and clean joining, relies heavily on high-power fiber lasers. These lasers offer exceptional beam quality and speed for tasks like welding copper and aluminum foils and sealing battery casings, which are critical for battery performance and safety. For instance, the automotive sector's application of fiber lasers, which was valued at $2.8 billion in a recent period, underscores this demand. The construction of massive battery gigafactories globally, which prioritize automated, efficient assembly lines, necessitates the use of fiber laser systems for high-volume, reliable production of battery components, accelerating the deployment of new laser systems on a global scale.</span></p>

<ul>

<li style="font-weight: 400;"><strong>Integration with Industry 4.0 and Smart Manufacturing</strong></li>

</ul>

<p><span style="font-weight: 400;">The global push for Industry 4.0, which emphasizes automation, connectivity, and intelligent systems in manufacturing, is significantly boosting the demand for fiber lasers. Fiber lasers are essential tools in modern smart factories, easily integrating with Computer Numerical Control (CNC) systems, robotic arms, and Manufacturing Execution Systems (MES) for tasks like high-speed cutting, precision welding, and intricate part marking. Industry reports indicate that the use of CNC fiber lasers can improve production efficiency by 20-30% and cut energy consumption by up to 30% in automated environments compared to traditional methods. This efficiency and compatibility with automated workflows, minimizing human intervention and enabling real-time data feedback, align perfectly with the objectives of creating highly productive and cost-effective 'smart production hubs' worldwide.</span></p>

<ul>

<li style="font-weight: 400;"><strong>Miniaturization and Precision in Semiconductor & Electronics</strong></li>

</ul>

<p><span style="font-weight: 400;">The relentless demand for smaller, more powerful, and sophisticated electronic devices is a key factor driving fiber laser growth, particularly in the semiconductor and consumer electronics industries. Manufacturing advanced integrated circuits (ICs), flexible circuits, and micro-electromechanical systems (MEMS) requires ultra-high precision processing that traditional tools cannot match. The segment focused on ultrafast fiber lasers, which deliver high precision and a minimal heat-affected zone (HAZ), is expanding rapidly to meet this need. Key players are specializing in frequency-tripled ultraviolet (UV) fiber lasers for delicate tasks such as flexible circuit cutting and OLED display repair, underscoring the shift toward lasers that can process materials like glass and polymers with sub-micron accuracy, which is non-negotiable for modern electronics.</span></p>

<p><strong>Key Trends in the Fiber Laser Market</strong></p>

<ul>

<li style="font-weight: 400;"><strong>The Rise of Ultrafast Fiber Lasers for Micro-Processing</strong></li>

</ul>

<p><span style="font-weight: 400;">A prominent trend is the increasing adoption of ultrafast fiber lasers, including picosecond and femtosecond varieties, for micro-processing applications. These lasers are defined by their ultra-short pulse duration, which effectively ablates material with minimal heat transfer to the surrounding area. This capability, known as "cold processing," is vital for manufacturing sensitive components where thermal damage is unacceptable. A key application is the fabrication of medical devices, such as the precise drilling of catheter tubes or the intricate machining of biodegradable stents, where micron-scale features are common. Furthermore, in the electronics industry, ultrafast fiber platforms are finding significant uptake in processes like through-glass via (TGV) drilling in advanced semiconductor packaging, highlighting their essential role in next-generation device construction.</span></p>

<ul>

<li style="font-weight: 400;"><strong>Shift to Ultra-High Power and Multifunctional Hybrid Systems</strong></li>

</ul>

<p><span style="font-weight: 400;">The industrial sector is experiencing a definite trend toward fiber lasers with ever-increasing power outputs, now reaching and exceeding the 30 kW level. This leap in power directly translates to a greater ability to cut thicker, more challenging materials at dramatically faster speeds, boosting overall productivity in heavy industries. Major manufacturers, such as Coherent, are actively launching high-power laser series to meet this demand for cutting thick sheet metal and processing hardened alloys in sectors like shipbuilding and heavy machinery. Concurrently, a move toward hybrid technology is emerging, where a single fiber laser system integrates multiple functions—such as cutting, welding, and laser cleaning—allowing users to accomplish diverse processing tasks with the same machine, thereby reducing capital investment and floor space requirements.</span></p>

<ul>

<li style="font-weight: 400;"><strong>AI-Powered Integration and Predictive Maintenance</strong></li>

</ul>

<p><span style="font-weight: 400;">A major emerging trend is the integration of Artificial Intelligence (AI) and Machine Learning (ML) into fiber laser systems to create 'smarter' machines. These advanced systems use embedded software and sensors to collect real-time data, enabling a level of automation beyond simple CNC control. For instance, AI algorithms are now being developed to optimize the cutting route in real-time, forecast the wear and tear of consumables like nozzles and lenses, and automatically adjust laser power and focus based on material thickness. This predictive maintenance capability reduces unexpected downtime, a critical factor in high-volume production lines. The focus is on creating autonomous laser systems, such as the "Intelligent Cutting Process" technology from companies like Bystronic, that can manage complex operations with minimal human intervention.</span></p>

<p><span style="font-weight: 400;">We explore the factors driving the growth of the market, including technological advancements, consumer behaviors, and regulatory changes, along with emerging </span><a href="https://www.imarcgroup.com/fiber-laser-market"><strong>fiber laser market trends</strong></a><span style="font-weight: 400;">.</span></p>

<p><strong>Leading Companies Operating in the Global Fiber Laser Industry:</strong></p>

<ul>

<li style="font-weight: 400;"><span style="font-weight: 400;">ABB Ltd.</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Amonics Limited</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Apollo Instruments Inc.</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Coherent Inc.</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Cy-laser S.r.l.</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">IPG Photonics Corporation</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">MKS Instruments Inc.</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Omron Corporation</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">NKT Photonics A/S</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Toptica Photonics</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Trumpf GmbH Co. KG.</span></li>

</ul>

<p><strong>Fiber Laser Market Report Segmentation:</strong></p>

<p><strong>By Type:</strong></p>

<ul>

<li style="font-weight: 400;"><span style="font-weight: 400;">Infrared Fiber Laser</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Ultraviolet Fiber Laser</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Ultrafast Fiber Laser</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Visible Fiber Laser</span></li>

</ul>

<p><span style="font-weight: 400;">Ultrafast fiber laser exhibits a clear dominance in the market due to its high precision and efficiency in applications requiring ultrafast pulses.</span></p>

<p><strong>By Application:</strong></p>

<ul>

<li style="font-weight: 400;"><span style="font-weight: 400;">Cutting</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Welding</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Marking</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Fine and Micro Processing</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Medical</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Others</span></li>

</ul>

<p><span style="font-weight: 400;">Cutting holds the biggest market share, as fiber lasers are widely used for precision cutting in industries like automotive and aerospace.</span></p>

<p><strong>Regional Insights:</strong></p>

<ul>

<li style="font-weight: 400;"><span style="font-weight: 400;">North America (United States, Canada)</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Latin America (Brazil, Mexico, Others)</span></li>

<li style="font-weight: 400;"><span style="font-weight: 400;">Middle East and Africa</span></li>

</ul>

<p><span style="font-weight: 400;">North America dominates the market owing to its advanced manufacturing infrastructure and increasing demand for high-tech laser systems.</span></p>

<p><strong>Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.</strong></p>

<p><strong>About Us:</strong></p>

<p><span style="font-weight: 400;">IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.</span></p>

<p><strong>Contact Us:</strong></p>

<p><span style="font-weight: 400;">IMARC Group</span></p>

<p><span style="font-weight: 400;">134 N 4th St. Brooklyn, NY 11249, USA</span></p>

<p><span style="font-weight: 400;">Email: sales@imarcgroup.com</span></p>

<p><span style="font-weight: 400;">Tel No:(D) +91 120 433 0800</span></p>

<p><span style="font-weight: 400;">United States: +1-201971-6302</span></p>